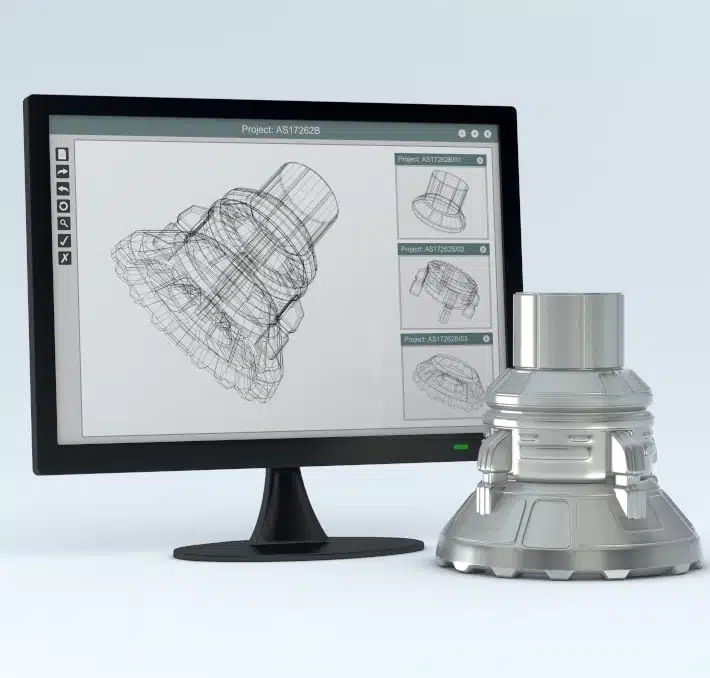

A Digital Thread is a data-driven architecture that connects information across the entire product lifecycle—from design and manufacturing to service. It forms the foundation that links data flows from various sources—such as CAD, ERP, and CRM systems—into a coherent, traceable context.

Learn more about how a Digital Thread breaks down data silos and connects your entire product lifecycle.

The result: a continuous flow of information that ensures interoperability, accelerates change processes, and lays the foundation for sustainable innovation and digital transformation.

Discover how a PLM system enables a seamless Digital Thread in our blog. Learn More →

The Digital Thread revolutionizes how products are developed. This data-driven architecture enables the integration of information throughout the product lifecycle. In our whitepaper, we demonstrate how PLM software can be used to create a Digital Thread, improving communication and linking cause and effect. Learn how a Digital Thread can link complaints with the corresponding parts.

A Digital Thread is a data-driven architecture that connects information across the entire product lifecycle—from design and manufacturing to service. It forms the foundation that links data flows from various sources—such as CAD, ERP, and CRM systems—into a coherent, traceable context.

AGi32 boasts a wide array of features, including: