How Geopolitics Are Rewiring Manufacturing Operations Learn more

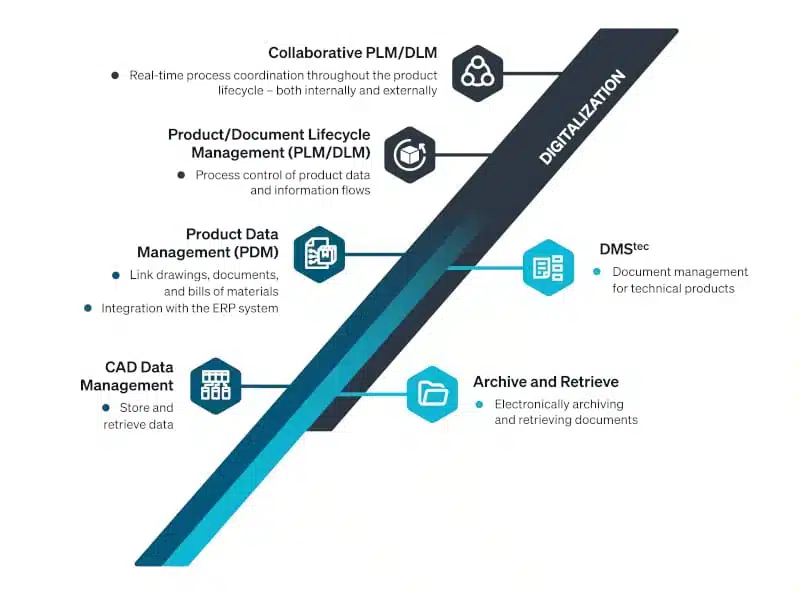

DMStec centrally connects technical product structures and related documents to enable efficient, revision-proof workflows. It simplifies management of all product information throughout the lifecycle, ensuring quick, secure access and clear traceability at every stage.

DMStec solves this problem by managing technical components, systems, or machines as digital structures, regardless of where the documents are stored. The result is a shared, transparent data basis that provides all stakeholders with quick and secure access to current, context-related information.

With DMStec manage all documents and information in one place

These differentiated features ensure secure and precise document management, enabling every department to find exactly what it needs—without duplication or redundancy.

The effect: less effort, lower costs, and significantly fewer errors thanks to seamless, media-break-free processes. At the same time, quality, efficiency, and transparency increase across the entire product lifecycle — from engineering to service.

Thanks to deep integration with ERP, CAD, and Office systems, DMStec supports your digital transformation in an efficient, compliant, and future-proof way.