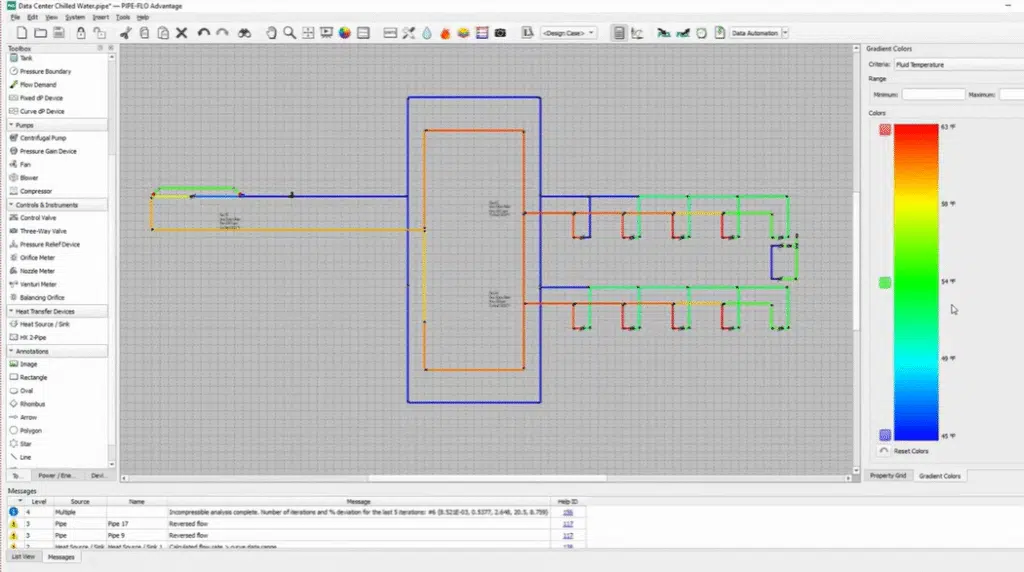

As temperature behavior becomes a more critical design factor, especially in systems with tight performance margins or intermittent operation, engineers need tools that can model not just how a system performs, but how it responds over time. This new feature enables simulation of time-based thermal changes to support more accurate planning for storage, control, and failure scenarios.

Model and size tanks to maintain thermal stability across your system. Explore how tank size, location, and flow affect temperature profiles during operation.

Simulate equipment downtime scenarios like pump or chiller failures. Identify how quickly temperatures will rise or fall, and where critical limits are reached.

Use Overtime logic to model system responses to shifting conditions. Automatically adjust valves, pumps, and isolations when operating constraints are breached.

Visualize fluid movement during system flushing to ensure compliance with velocity and exposure requirements. Understand the effectiveness of chemical or thermal treatments in real time.