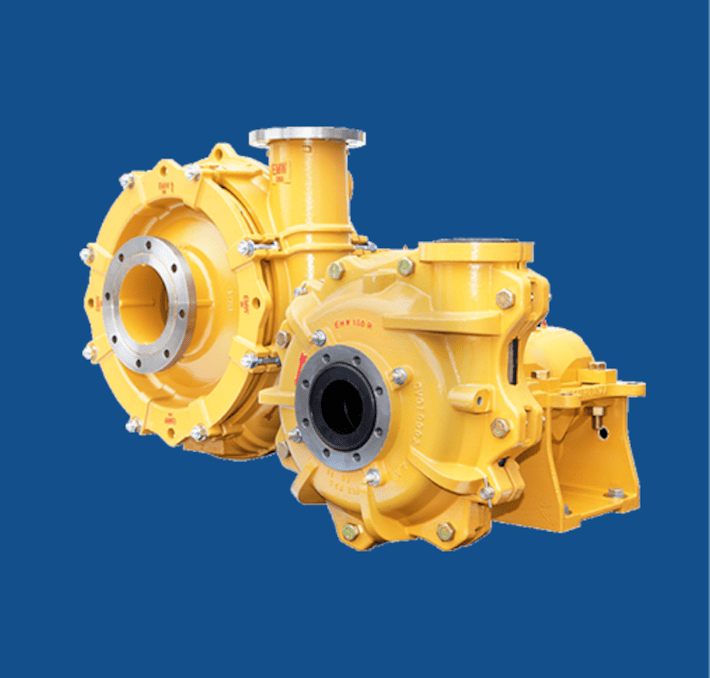

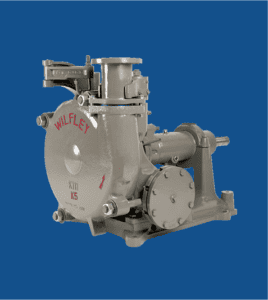

Think of Arthur Redman Wilfley, a genius inventor who devised many patented devices, including a table to separate gold from other elements and a packingless centrifugal pump designed specifically for mining applications. His discoveries gave birth to A. R. Wilfley and Sons, a now almost century old Denver, Colorado-based pumping systems manufacturing company that sells to markets across the world. Still family-owned, Wilfley calls itself a “proud, independent” innovator in their field with 12 product lines that serve ammonium nitrate, cement and aggregate, chemical processing, fertilizer, food, beverage, water — and of course, mining — industries. “We create and sell a niche product so we go about things differently,” notes Mark Scott, Sales and Marketing Assistant (aka “Guru”). “We have great employees who believe all of us should go above and beyond every day. We take full responsibility for the entire pump. We will never tell you the seal problem is someone else’s concern.” Wilfley’s long-standing traditions of inventiveness, great products and superior customer service also sum up the reasons why the firm turned from a more “generic” sales configuration software provider to Intelliquip.