Implementing an Engineering Change Management (ECM) process is a best practice for any company. Done well, your ECM can optimize design and development, boost productivity, and accelerate your ability to bring game-changing products to market. In other words, the quality of your ECM can directly influence your revenue and your reputation.

But there’s more to an ECM than just setting and forgetting it. Without the right implementation and guidance, an ECM process can lead to bottlenecks, flawed decision-making, higher costs, and increased errors.

Your team might run into duplicate change requests or some requests might fall through the cracks. Supporting documents can go missing when you want to check the background of a certain design change. Or maybe they’re just stored away across a dozen hard drives, CRM and ERP systems, servers, and file shares. Any of these scenarios can make it tough for you to determine what information is up-to-date and what isn’t.

What kind of visibility do you have into your Engineering Change Management (ECM) process? How many changes are underway? What deadlines does your team have to meet? What costs are involved? It’s probably hard to say if you can’t view all Engineering Change Requests (ECRs) in one place. Combine this lack of transparency with a slow, manual approval process and it can take ages to make a needed update.

The longer it takes to complete an Engineering Change Order (ECO), from initial concept to launch, the longer your team is diverted from working on new, value-adding projects. While minor ECOs might take a week or less to process, more complex ECOs might take a few weeks. Major ECOs, such as a product line redesign, often take five months or more.

It’s no mystery that many organizations want to sharpen and accelerate their ECM process — it can open the doors to stronger revenue and a competitive edge.

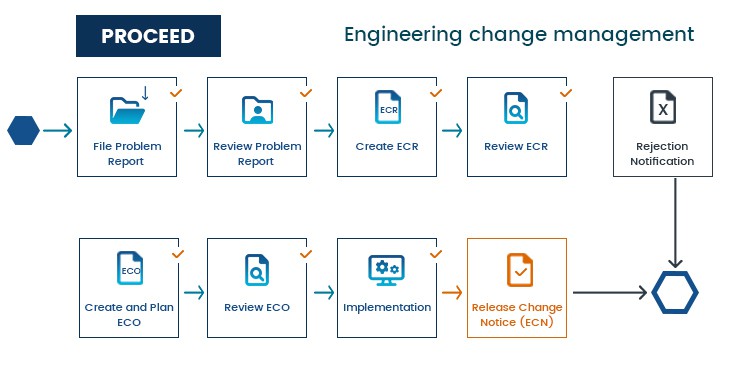

The basis of a great Engineering Change Management (ECM) is a standardized and transparent plan for all engineering changes. Centralized document storage gives your team access to the right information (like CAD and analysis files) so they can make decisions with accurate, complete data.

Approval should be quick and easy while documenting who owns an ECR and who is accountable for completing it. Key metrics should be tracked for continuous improvement. Put these elements together and you’ll reduce errors, improve collaboration, increase productivity, and get ECRs right the first time.

PRO.FILE‘s PLM/PDM tools that can help your team follow ECM best practices and ensure everyone stays on the same page. Here’s how:

PRO.FILE enable smarter Engineering Change Management (ECM) practices through the entire product lifecycle. The results are quicker approvals, faster time to market, higher product quality, cost savings, and a more efficient team. With these solutions, your teams can get started on profitable projects instead of re-doing tasks that weren’t done right the first time.

In today’s complex engineering environment, where leaders must manage multiple teams and multiple projects at once, no other tools help engineering changes go quite as smoothly — or drive more impressive outcomes.