ebook:

TOP 10 CPQ FUNCTIONS FOR MANUFACTURERS

While engineering to order creates flexibility for manufacturers, the solution also comes with a few hurdles. To become a successful ETO manufacturer, you need a robust CPQ solution to help you tackle challenges like these:

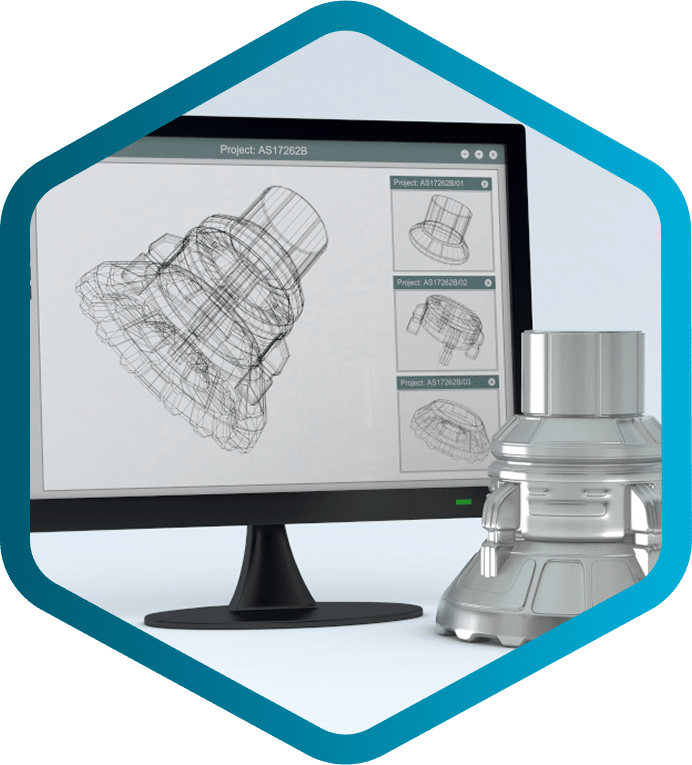

If you’re interested in switching to manufacturing ETO, you need software that can keep up. That’s where Configure One Cloud’s CPQ software comes to the rescue. It allows you to create products with hundreds of customization options using parameters set by your engineers.

Our CPQ software can even automate repetitive tasks so your teams can focus on innovating new products. Here’s a look at some of the ways Configure One Cloud software can help: