Decades ago, manufacturers could only draw product designs by hand. Every single draft required painstaking effort, slowing down design output and limiting revenue for companies. Now in the digital age, Computer Aided Design (CAD) software has revolutionized the way manufacturing designers create products — improving efficiency, creating better quality renderings, and creating massive cost savings.

Some manufacturers have chosen not to invest in CAD because they don’t see the value, but they’re missing the bigger picture of what design software offers. After all, sticking with manual drafting processes inhibits product development.

Here, we’ll cover just some of the ways CAD software can unleash designers’ full creative potentials.

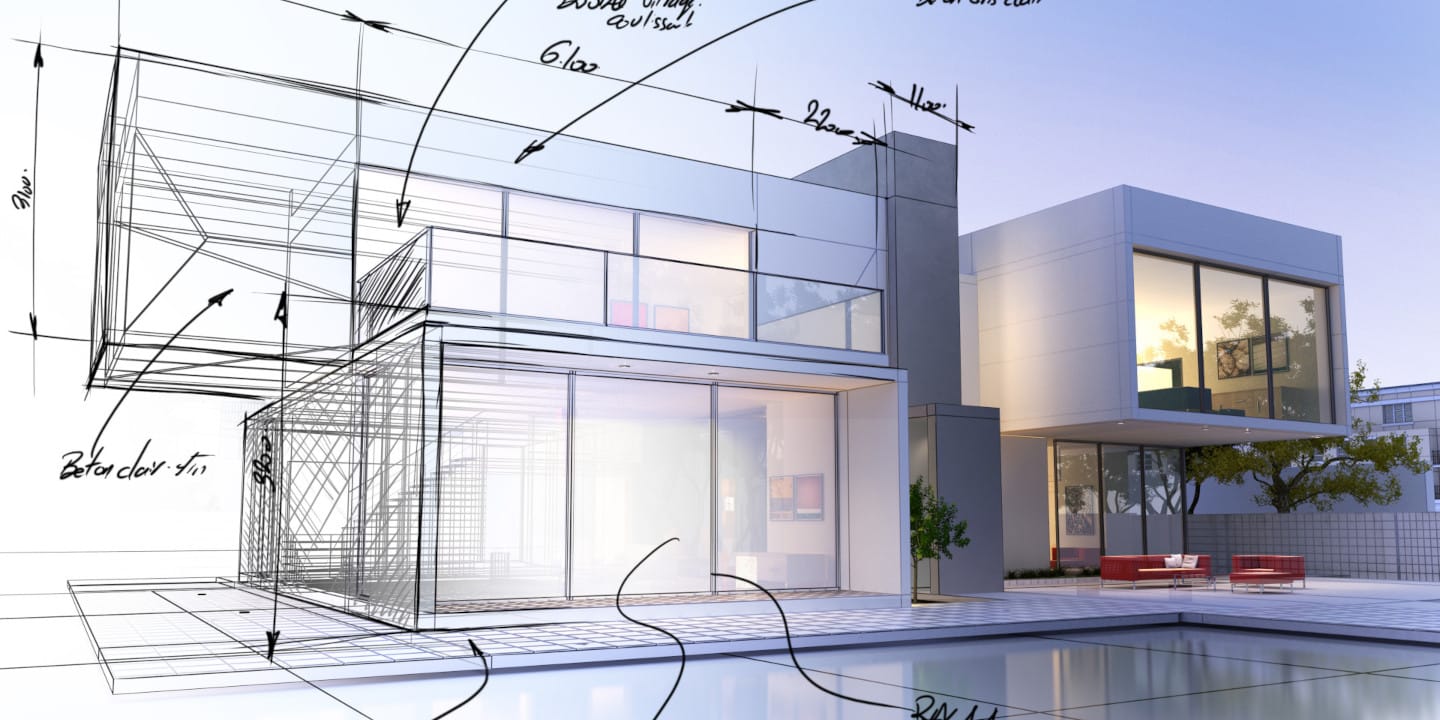

CAD software is well-known for helping designers create 3D renderings of objects that customers and project stakeholders can rotate to see from every angle. Many modern CAD programs take rendering a step further by allowing designers to place textures on their creations and even customize lighting.

In the right conditions, designers can even produce photo-realistic images that help stakeholders and customers envision products in specific spaces. This helps designers create more aesthetically pleasing objects, and helps sales teams close more deals.

CAD has been utilized for more than 30 years, but not all platforms are created equal. Revalize offers some of the most advanced capabilities in the marketplace. Industry-leading design begins with CAD software that offers industry-specific features and streamlines material documentation.