Simplify your product management process with product lifecycle management software. Enhance collaboration, data accuracy, and streamline the product lifecycle.

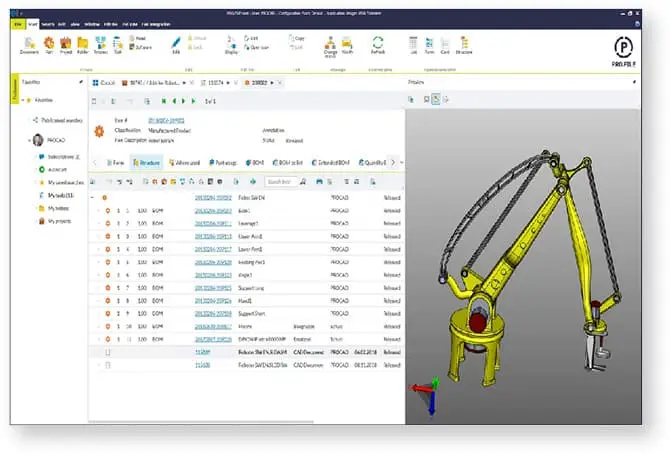

Our Product Lifecycle Management (PLM) software combines product information from start to finish, including design, manufacturing, service, and disposal. It uses methods, processes, and structures along with IT systems to manage data effectively.

Ensuring products meet industry standards and regulations guarantees safety, quality, and legality. This involves thorough testing, certification, and documentation. Non-compliance can lead to recalls, fines, and reputational damage. Regulatory compliance maintains consumer trust and avoids legal issues.

Ensure that products meet industry standards and regulatory requirements.

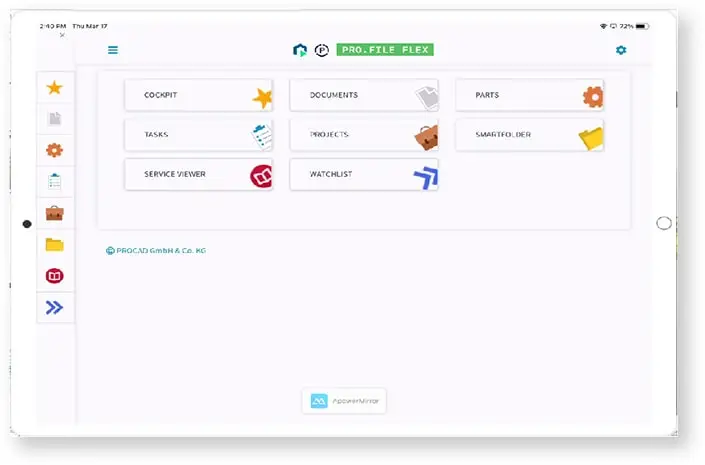

As more products include software and electronics requirements, the need for flexibility, agility, and variant management increases. These factors drive digital engineering and product management, from product engineering to operations, making forward-thinking product lifecycle management software a must.

PRO.FILE PLM and keytech PLM, both powerful software solutions, integrate with other enterprise systems.