streamlines complex order configuration

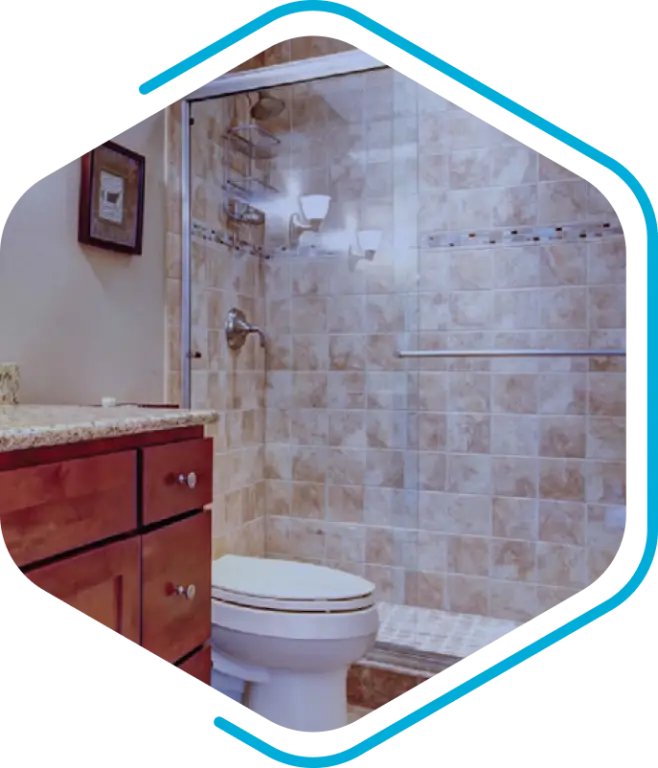

Quality Enclosures, Inc. provides high-quality shower enclosures and tempered glass. Since it was founded in Long Island, NY in 1963, the company has grown nationally, adding manufacturing facilities, tempering plants and distribution hubs in Florida, Georgia, Tennessee, South Carolina and Virginia.

As the company grew and changed its corporate structure, it needed a more robust and customizable ERP. It also wanted to streamline its complex, manual sales order configuration process.

Quality Enclosures selected NetSuite as its ERP and Configure One Cloud to automate and simplify configuration for its highly customized products.

NetSuite adapts to the company’s new corporate structure and enables it to better control inventory. Configure One Cloud cuts the time and expertise necessary to configure orders while reducing errors.

Nick Papas,

Quality Enclosures