The management team at Scranton Products management team started their search for a Configure, Price, Quote (CPQ) solution after dealing with repeated bill of material errors and a quote lead time of a week or longer. They were looking to streamline their entire quote-to-production systems and eliminate errors caused by manual configuration.

Since implementing Configure One Cloud’s CPQ solution, Scranton Products has been able to reduce lead times for quotations and drawings from nearly ten days to just a matter of minutes. Configure One Cloud also enabled Scranton’s dealers to create quotations and drawings without ever involving the company’s sales department.

Improvements to BOM accuracy have helped reduce the number of product returns and customer credits by 45% in the year after going live with Configure One Cloud and an additional 50% the year after that.

Scranton Products, located in Scranton, Pennsylvania, manufactures a wide variety of synthetic commercial building products for locker rooms and restrooms. Their products include locker systems, bathroom partitions, counter tops, and shower stalls. Scranton Products also markets and manufactures products for industrial use focused on the marine and semi-conductor industries.

“Our previous process was very manual and time consuming.”

In October 2007, Scranton Products’ management team recognized the need to streamline the company’s estimating, quotation, and order processing systems. They wanted to streamline their cumbersome quote-to-order process and eliminate BOM errors.

“Our previous process was very manual and time consuming,” said Gil Garcia, Director of Sales Operations. “When a dealer requested a quotation, it went to our estimating department. They created the quote and sent it back to the dealer. We would wait for a purchase order then start the cycle of producing a drawing for the project.”

Scranton Products began searching for a CPQ solution that could meet all of their requirements in October 2007. In addition to BOM generation, they wanted a CPQ that could integrate with SAP, their ERP system.

“We selected Configure One Cloud’s CPQ based on its capabilities and value,” Garcia said. “It was also very important that we felt comfortable with the company.”

Scranton Products signed a contract with Configure One Cloud in December 2007, and by June 2008 was live on Configure One Cloud’s CPQ solution. The team at Scranton Products collected product knowledge and Configure One Cloud personnel help set up the product rules.

“The system development was a collaboration,” said Garcia. “Using Configure One Cloud’s admin tools, we created the configuration rules for additional products,” said Garcia. “We are now self-sufficient.”

The initial implementation of Configure One Cloud was limited to just stalls and screens. Scranton Products has since added more product lines and the ability to showcase products through Configure One Cloud has further enhanced the company’s position as a leader in the marketplace.

“We have a competitive advantage with Configure One Cloud,” Garcia explained. “We’ve added benches, vanities, spare parts, and we’re in the process of adding lockers. We are in a position of having a complete range of products that none of our competitors can match.”

Another important part of the project was the seamless integration of Configure One Cloud to SAP, Scranton Products’ ERP system. As a result of this integration, they’ve eliminated saved time and eliminated errors from having to enter information in multiple systems.

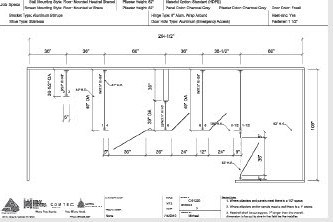

The second phase of the project made use of Configure One Cloud’s Real Time 2D module. This enabled users to see the impact of dimensional choices and various options within a 2D drawing while making selections.

“We’ve dramatically increased the speed by which we can get drawings in the hands of our customers,” said Garcia. “Now, dealers can create configurations without our help. They can make adjustments and then instantaneously see the results.”

Before Configure One Cloud, this process would take anywhere from three to ten days. Today, dealers can create their own drawings and quotes in a matter of minutes.

Scranton Products has realized many benefits from using Configure One Cloud, including a dramatically faster turnaround time for creating drawings and quotations, as well as significantly improved BOM and pricing accuracy.

“If the BOM is not accurate,” said Garcia, “then the factory manufactures the wrong product, resulting in returns and a credit back to the customer.” By improving the BOM accuracy and dramatically reducing configuration errors, Scranton Products has reduced product defects/returns and customer credits issued as a result of those returns.

In 2008, Scranton Products was able to reduce credits by 45%. In 2009, they managed to reduce those levels by an additional 50% against the 2008 levels.

– Gil Garcia

Director of Sales Operations Scranton Product

Recognizing the benefits that Configure One Cloud brought to the company, Scranton Products took the opportunity to make organizational changes to improve customer service.

“We were able to combine the order entry and customer service departments,” said Garcia. “We changed the focus and name of the group to Customer Advocacy,” The department was tasked with being the internal champion for Scranton’s customers.

“They can focus on building customer relationships and manage everything from the processing of the order through to delivery,” said Garcia. “They now have the capability to create a drawing, process orders, manage customers’ expectations, and keep customers informed on day-to-day activities.