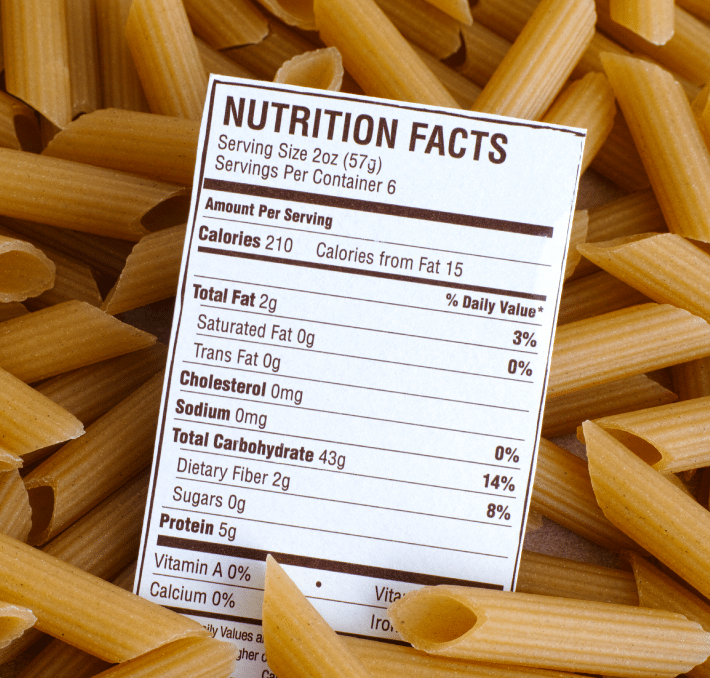

Top 5 Challenges in Nutrition Labeling

Nutrition labeling can be difficult. Luckily, PLM software solves many common nutrition labeling challenges.

Navigating Success: Overcoming Challenges in the Food and Beverage Industry

Discover the latest trends in the food and beverage industry. Stay informed about the most innovative products and practices.

The Link Between Resilient Supply Chains and Agility

Transform your approach to supply chain management by improving resilience against inflation and global disruptions.

Food & Beverage Cloud Based PLM Solutions

Explore how food & beverage cloud based PLM enhances project visibility and collaboration in manufacturing for better workflows.

PRO.FILE Manufacturing Report 2025

Download our report to learn why 64% of organizations surveyed are spending more on product lifecycle management (PLM) software than they did a year ago—and how they plan to use it.

SpecPage Manufacturing Report 2025

Companies in the food and beverage industry use product lifecycle management (PLM) software to streamline processes and maximize productivity. Download our report for details!

GDSN Guide for Food Industry Supply Chain Solutions

Discover the benefits of the GDSN Guide for Food Industry in improving resource conservation and data utilization.

SpecPage GDSN Guide for Food Industry Success

Explore the SpecPage GDSN Guide and learn how it helps food manufacturers manage product data effectively.

PRO.FILE V10: Key Advantages for Your Business

Discover the features of PRO.FILE V10, including real-time collaboration and flexible automation that optimize business processes.