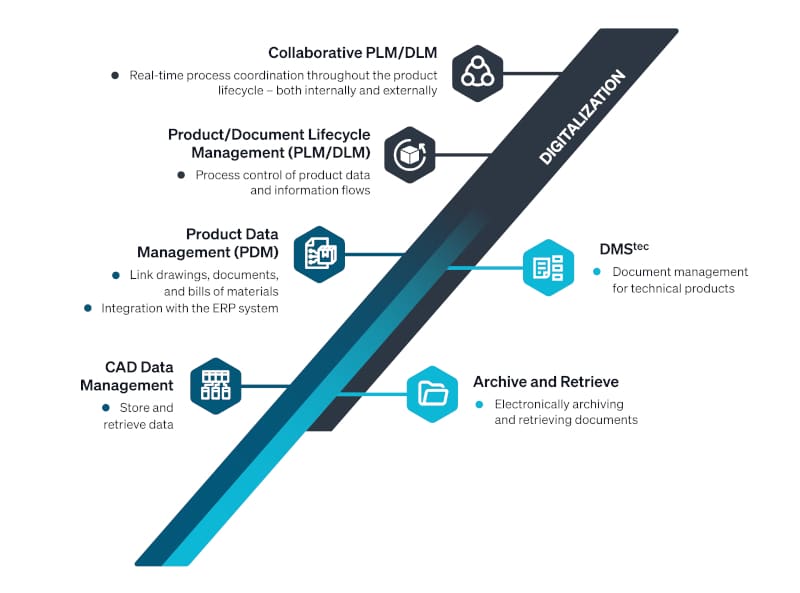

Document Management System (DMS) with PRO.FILE establishes a new level of quality in document-based collaboration across departments and throughout product stages for enterprise-wide document management and cutting-edge product management. It allows for technical structure mapping and, with Project Lifecycle Management (PLM) software, forms the basis for mapping digitalized processes.

Technical companies often push conventional document management systems (DMS) to their limits due to their complex environments. Traditional DMS struggle with the intricate relationships between technical documents like drawings and specifications, and the technical product structures they relate to. For this reason, a specialized DMS known as “DMS” has emerged to address these needs. Technical companies should carefully evaluate DMS vendors to ensure their solutions can integrate product-specific documents with existing structures, facilitating digitalized information-based workflows.

DMS can manage a variety of documents, including letters, contracts, documents, orders, reports, acceptance and process documents, specifications, and service notifications from archiving through permissions to versionings.

Companies looking to digitalize based on a single source of truth need to connect their product and infrastructure data to their technical documents. No matter where you are in the process, DMS can get you where you need to be.

Using innovative apps and solutions for mobile access, DMS provides information to customers no matter where they may be.

With DMS we offer a holistic solution that provides a complete perspective on all relevant company information. The features and functionality make it possible to capture and manage documents and information from various sources and systems easily and conveniently, enabling intuitive data access to realize the full benefit of an enterprise-wide information platform in a cross-functional, mobile manner.

Having PRO.FILE display these documents within the context of the power plant’s structure in day-to-day operation is extremely helpful. We never had anything like this structured and part-centric storage system in any of our previous power station units. With DMS and the built-in check-in/check-out mechanisms, we are also eliminating the risk of working with outdated versions.”

Thomas Burg,

DMS Administrator and ECAD designer, Netzgesellschaft Düsseldorf mb